Quality is one of our most prized values

olives to reach our premises still fresh, juicy and of a vibrant green colour. We process the olives by desalting them, making the fruit more palatable to our customers and easier to consume. To ensure products of the highest quality, we decided to import the raw material fresh from the maker, and then directly oversee all the aspect of the production progress, here, in our Kanagawa factory. This way we can ensure that our products are up to the standard of the Japanese market. We can proudly say to be one of the largest company in Japan to import fresh olives directly from overseas producers, process them, and mass produce table olives on the territory.

You can see how our delicious olives are made by visiting the following link

Olives are imported from Italy in refrigerated containers.

Our suppliers in Europe harvest the table olives in autumn, debitter and then preserve them in barrels filled with brine. Fresh olives are debittered without undergoing the fermentation process and, for this reason, require refrigerated storage. If left at room temperature, they will naturally start to ferment and become unsuitable for consumption. By using refrigerated containers we prevent fermentation, and the olives will arrive to us still fresh and of a vibrant green. Traditionally, olives are debittered through lactic acid fermentation. This process takes up to 5 months, which means that olives harvested in autumn will have to wait until the next spring to be ready for consumption. Some 200 years ago, French people discovered a way to debitter olives overnight, using lye (an alkali metal hydroxide). This way, harvested olives don’t have to wait half a year to be eaten. Japan imported this method in fairly recent times, and olives processed through this method are called “shin zuke”, freshly pickled. Shelley’s “Freshly Pickled Olives” are imported fresh from Italy, stored in a controlled refrigerated ambient, and can be shipped still fresh throughout the year.

Desalination, pH regulation and packaging

Imported drums are inspected and undergo a process called desalination. By adjusting the salt concentration, we can change the flavour of the fruit. This is one of the most prominent reasons that led us to import our olives fresh: determine the flavour of our olives. With fresh raw materials we can create Shelley’s original flavour.

Pasteurization

Desalted olives are sealed in bags with their brine (for pH regulation purposes, citric acid and tartaric acid are added). By pasteurizing our products, we keep ensure our customer’ safety and also extend shelf life of products. Also, once pasteurized, our olives maintain their freshness and flavour for a few months. Since pasteurization is carried out at low temperatures, olives need to be kept refrigerated.

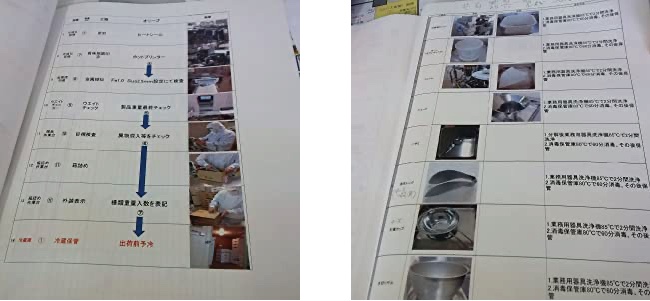

Process Flowcharts and Standard Operating Procedures

Quality control requires constancy and continuity to bear fruits. It is important to always provide the customer with the same quality standard. Each and every of our products must be up to this standard. For this reason, we at Shelley’s carry out production following standardized procedures and manuals, keeping check of every part of the manufacturing process and ensuring that all employees comply to the shared guidelines.